Heat sensitive products like Ibuprofen powder are difficult to compact and tend to stick to punch surfaces during tableting process. Furthermore, they can have a poor flowability and often cannot be fed into die. As a result, there are high variants in tablet weight due to the inhomogeneous die filling.

Powder is temperature sensitive and starts sticking after 35°C

Sticking issues (film) on die table

Sticking issues on the punch surface

Powder is sticky from the start

Powder does not flow well

Powder cannot be fed into die as it does not flow

High variations in tablet weight due to inhomogeneous filling

Better product flow into feeding tube

No product jam in the feeding tube

Increased turret rotation speed

Tablet press, die table and punch tips do not exceed 30°C during the process

No sticking issues on die table or punch tips

Homogeneous filling of the die

Use of our KiTech to test your application

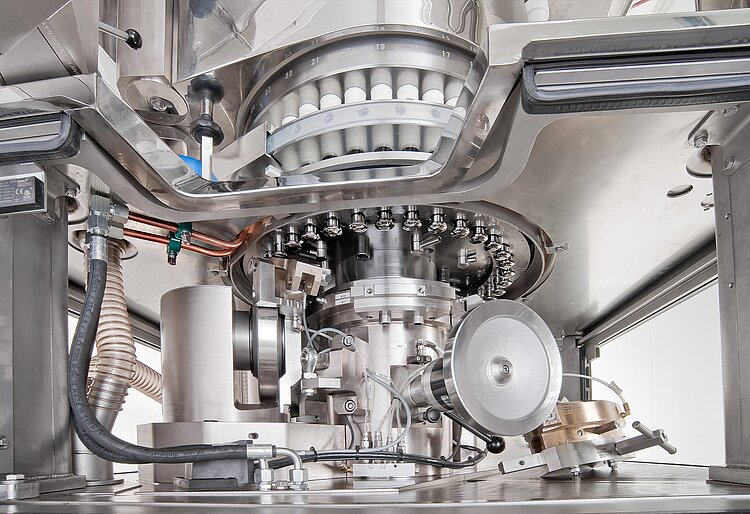

Production of IBUPROFEN which runs on a Synthesis 700 with 40 rpm turret rotation speed. Goal: Increased machine output speed and a continuous production without any cleaning issues.

Our KiTech can help you find the right customised Kilian Solution. Moreover, our KiTech supports you e.g. with speed demonstrations and optimisation as well as analyses and optimisation of existing tableting processes.