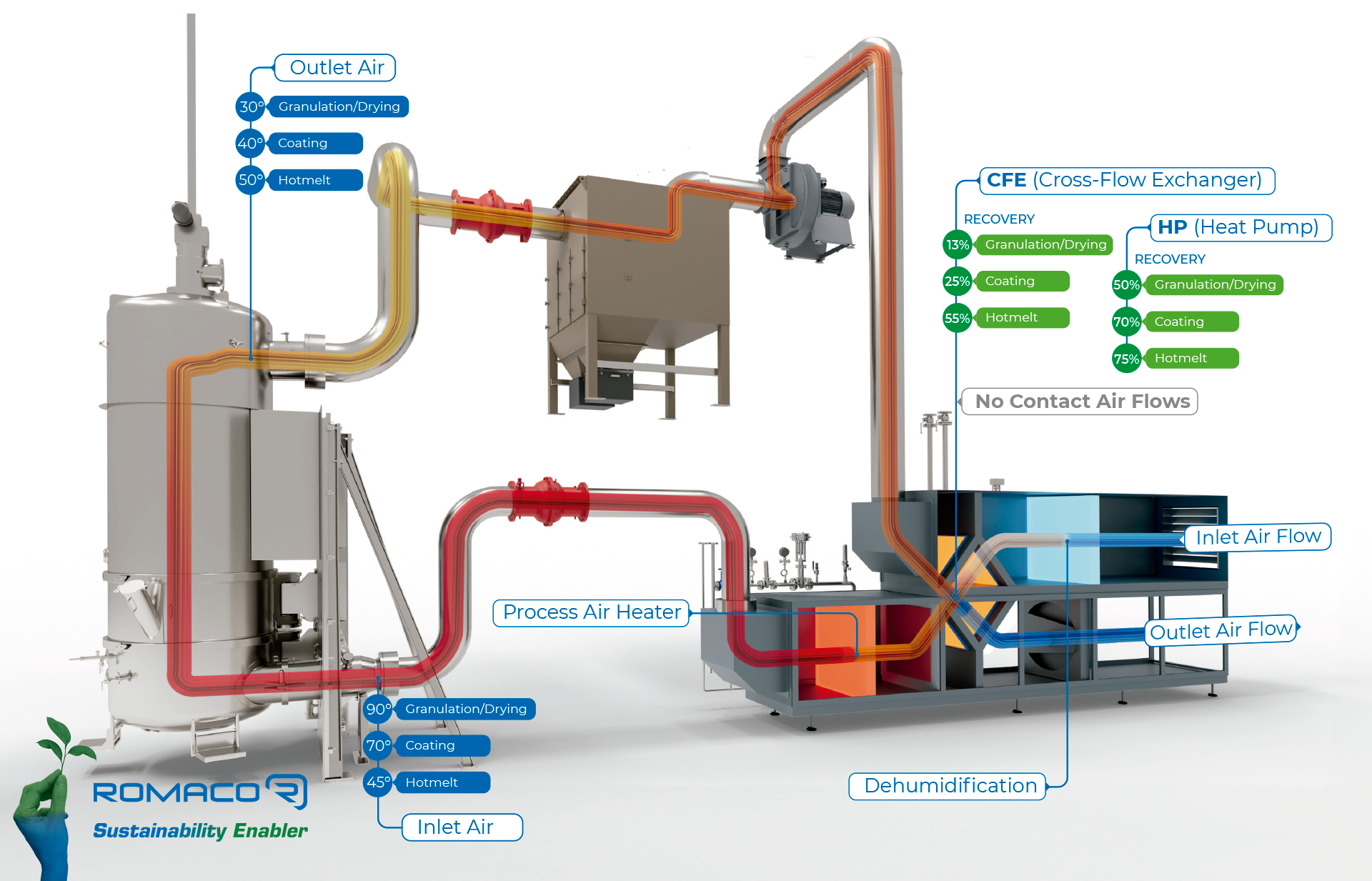

In the world of industrial processes, finding ways to save energy, reduce costs, and be more eco-friendly is vital. The Innojet Heat Recovery System, using a crossflow heat exchanger plate, can help you achieve this. It works by transferring heat from the outgoing air to the incoming air directly. This innovative system can save you between 13% and 55% of your energy, making it a game-changer for more efficient and sustainable production.

If you're dealing with energy-intensive processes that are driving up your costs, struggling with high production expenses, trying to cut down on waste, or looking to be more sustainable, these are the common challenges you might be facing:

The Innojet Heat Recovery System is here to help. Here's how our solution can address your challenges:

| Process | Inlet air | Oulet air | CFE recovery | HP Recovery |

| Granulation | 90°C | 35°C | up to 15% | up to 50% |

| Coating | 70°C | 45°C | up to 25% | up to 70% |

| Hotmelt | 45°C | 55°C | up to 55% | up to 75% |

In a world where saving energy and embracing eco-friendliness are crucial, the Romaco Innojet Heat Recovery System stands as a simple yet effective solution. This innovative system not only helps reduce costs, minimize waste, and promote sustainability but also tailors energy recovery to your specific applications. Seamlessly aligning with the recent EU CSR Directive amendment, urging companies to prioritize sustainability, Innojet ensures that your production process adheres to responsible and eco-friendly practices. Don't miss the chance to elevate your production efficiency and environmental responsibility. Step into the future with the Innojet Heat Recovery System—a practical solution for a brighter, more sustainable tomorrow.

Drying of wet granulate (dryer)

Granulation by top spraying (granulator)

Coating by bottom or tangential spraying (coater)

Do you need more information?

Please do not hesitate to contact us if you require further information regarding our Coating equipment or if we can assist you in any other way.