In the pharmaceutical industry, equipment flexibility allows direct scale-up from R&D application to pilot scale or even to industrial production. These scale-up procedures usually have to be performed several times during the commercial cycle of most pharmaceutical products

Scaling-up manufacturing operations to meet commercial requirements

Minimising resources during the scale-up processes

Archiving the reproducibility and robustness of the process

Finding simple solutions to facilitate changes in registration dossiers

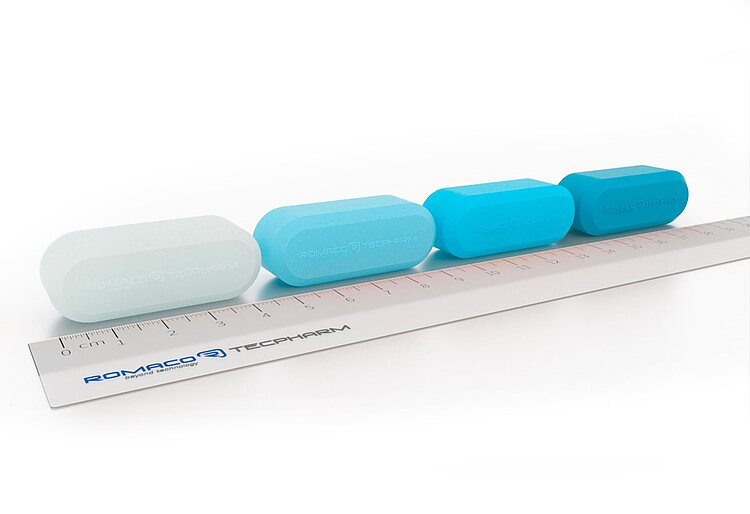

The Optima technology enables a direct scale-up process from 10% to 100% with a single machine

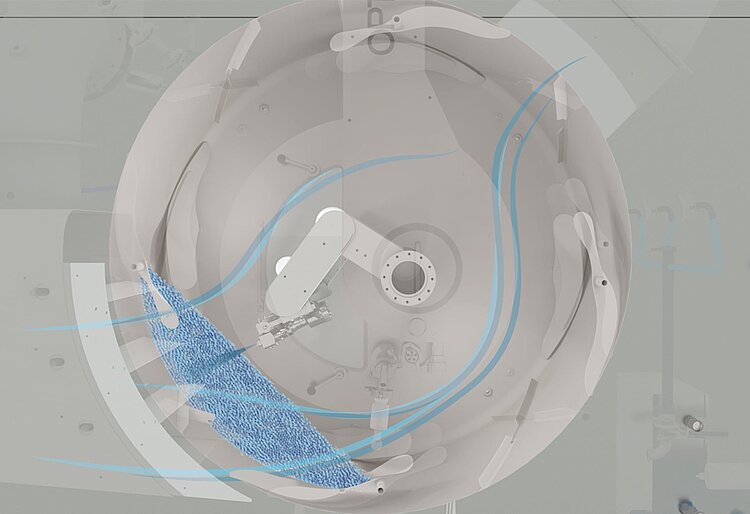

The Optima tablet coater provides easy control of spray ratios, distance between spray gun and tablet bed and self-adjustable path of drying air.

The Optima coater series minimises the number of equipment and maximises the use of the GMP surface area.

The Optima technology reduces the time required to increase the batch sizes in the commercial area

Increases the batch size range from 10% to 100%

Optimises the parameter adjustment fully automatically

All in the same drum, no time-consuming drum changes

Automatic arm extension system in terms of distance and angle

Automatic adjustment by sonar depending on the level of charge

Air path and flow self-adjust according to tablet load for a perfect performance

Do you need more information?

At our CoaTech Laboratory, we will help you with any challenge you might face concerning the coating process. Please get in contact with us.