In the production area it is common to use the same final blend batch to compress different tablet strengths. Split core batches usually have different shapes and batch sizes, e.g. multi strength products.

Risk of assembly errors when changing coating drums

Increase in the number of inter-batch cleaning processes, cleaning sampling and cleaning verification

Delays in manufacturing process

No equipment assembly is needed when different batch sizes of the same product are coated

Drastic reduction of the inter-batch delay times

Increase of productivity when campaigns are carried out with the same product

Reduction of errors related to improper assembly of equipment

Increases the batch size range from 10% to 100%

Optimises the parameter adjustment fully automatically

All in the same drum

No time-consuming drum changes

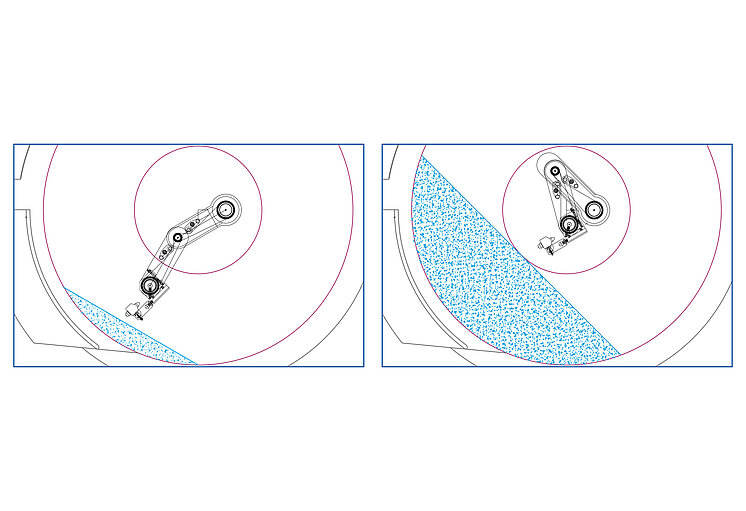

Automatic arm extension system in terms of distance and angle

Automatic adjustment by sonar depending on the level of charge

Air path and flow self-adjust according to tablet load for a perfect performance

Do you need more information?

At our CoTech Laboratory, we will help you with any challenge you might face concerning the coating process. Please get in contact with us.