When handling clinical, R&D or any small batch of high value products, the capability to minimise the product waste to virtually zero is key.

Among this kind of productions, we often find non-perfectly flowing powders and irregular powders, which present difficulties in obtaining an acceptable dosing accuracy.

There are also powders which are so hygroscopic, sticky or heat-sensitive that the typical filling processes can alter their properties and features.

Highly higroscopic and sticky powders

Irregular types of powders, cannot be accurately filled with vacuum-pressure dosing disk

Heat-sensitive powders, cannot be filled with augers without risking of altering their features

Citostatic products, posing hazard to operators

High value products in small and clinical batches

R&D products

Microspheres

RTU vials

Biotech

Non-flowable powders with tendency to create bridges

Powder that melts at 30° C

Microspheres which can’t be altered in any way during the filling process

Powders crystalised in bulk (instead of lyophilised in vials)

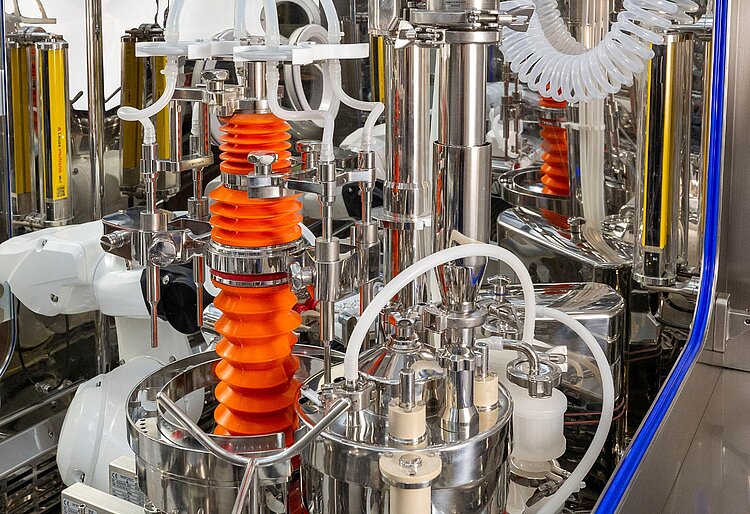

Innovative donut™ powder filling system via vacuum-assisted pick and place

Specifically designed hopper suitable to end-of-batch procedure leaving minimum product residual

Powder dosing starting from 20 mg

Choice among available barrier technologies: oRABS, cRABS and isolator, including integrated VHP decontamination system and transfer systems (RTP, SART system, etc.)

Zero-loss logic process thanks to robots taking care of all the operations (filling, stoppering, capping)

All vials are closed before exiting the machine

100% check weighing system

Possibility to run RTU vials in nests or trays

Peristaltic pumps for MediaFill purposes

Are you handling sticky, irregular powders difficult to dose with dosing disks or augers?

Do you need to process small batches of high value products?

Does your process require isolation technology?

Our MicroRobot 50 robotic filler and capper is ready to take over the challenge!