The Laboratory KiTech in Cologne, Germany is the expert centre for all your questions relating to the tableting process. KiTech, Romaco Kilian’s test laboratory, provides you with direct access to a wide range of tableting expertise, from recipe analysis through compression trials to analysis of your final product.

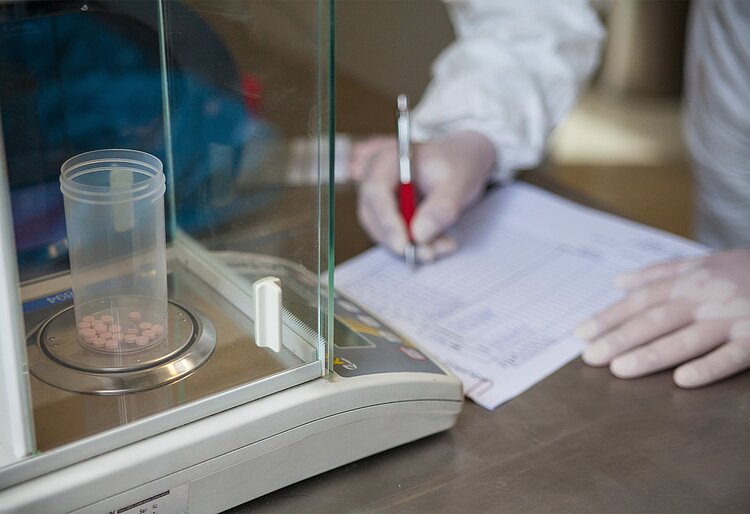

Using state-of-the-art analysis equipment and the all-in-one R&D instrument KTP 1X, Romaco Kilian’s KiTech particularly focuses on optimising your tableting processes and equipment to achieve maximum overall equipment effectiveness (OEE).

Performance improvement of tablet presses

Output improvement of tablet presses

Process speed improvement

Characterization of product and formulation

Sticky / temperature sensitive products

Capping and lamination of products

Provision of expertise in tableting special products e.g. hair colour, coal powder, algae powder, catalysts, veterinary drugs

Provision of expertise in tableting different product geometries

Support for the entire process from granulation to tableting and coating

Performance optimisation of tablet presses, e.g. by increasing the output or process speed

Characterization of products and formulations

Determination of characteristic tableting parameters, e.g. with hardness and compression force measurements

Comprehensive analysis of all required specifications for powder, granule and tablet production

Troubleshooting challenges like capping and lamination or sticky / heat sensitive products

Scale-up to identify the appropriate tablet press

Customisation of tablet presses for special applications

Testing of new machine features and machine developments

…and many more

Access to all current machine features such as: brake magnets, punch bellows, different fill shoe systems and smooth-running compression rollers

All-in-one R&D instrument KTP 1X

Six fully equipped press rooms and three conference rooms

Various production presses and analytical instruments

Comprehensive expertise, simulation tools and test possibilities

Expert team

Production of IBUPROFEN which runs on a Synthesis 700 with 40 rpm turret rotation speed. Goal: Increased machine output speed and a continuous production without any cleaning issues.

Production of effervescent tablets, customer visited a competitor to make trials with original product and 90.000 tablets/h. Goal: Increased machine output speed on a KILIAN tablet press.

Production of double layer dental cleaner effervescent tabs which runs on a KILIAN RX tablet press with 1,800 tablets/h. Goal: Increased machine output speed on a KILIAN SYNTHESIS 700 2G.

Production of fast dissolving tablets. Goal: Continuous production on a force feed rotary tablet press by using multiple punches and achieving the output capacity of 4 existing machines.

Our expertise covers the whole processing process. In addition to the KiTech services, we also help you optimise the flow behavior or the compressibility of powders and granules. Furthermore, if required, we support you in choosing the right coating solution for final tablets.

You already know what you want? Here are some questions to help us conduct your test.

You want to send test materials? Please send us your MSDS: