Some functional coatings require a large amount of coating to fulfill their purpose and therefore the process may last several hours, e. g. enteric coatings.

Increase of bed product level

Stops for adjustment of distance between bed and spray gun

Lack of homogeneity on coating

Lack of effectiveness of the functional coating

Continuous processes

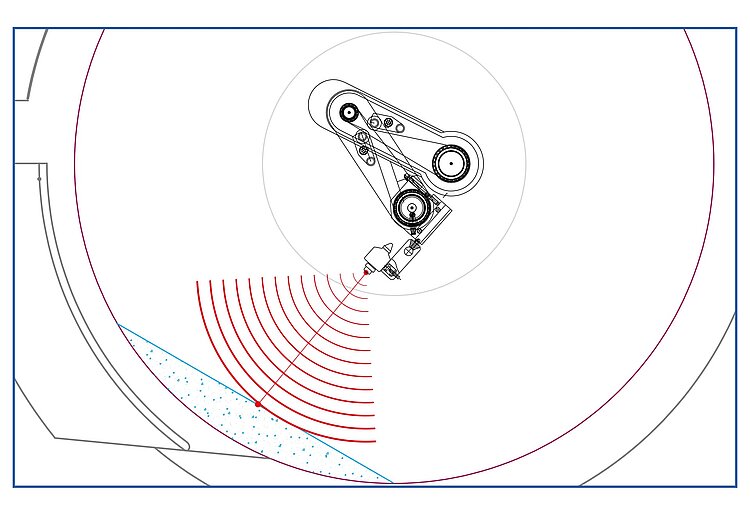

Ongoing monitoring of the distance between bed and gun by SONAR technology

Automatic regulation of the spray arm in length and angle

100% without operator errors

Increases the batch size range from 10% to 100%

Optimises the parameter adjustment fully automatically

All in the same drum

No time-consuming drum changes

Automatic arm extension system in terms of distance and angle

Automatic adjustment of the tablet bed-spray nozzles distance through continuous sonar monitoring

Air path and flow self-adjust according to tablet load for a perfect performance

Do you need more information?

At our CoaTech Laboratory, we will help you with any challenge you might face concerning the coating process. Please get in contact with us.