Romaco China Solids Process Center is located in Changsha, Hunan province, China.

It is a state-of-the-art expert center consist of Solids process development laboratory and Showroom for our advanced technology based process equipment to extend our high level support to the China & Asian market.

Are you interested in knowing more about it?

Our highly qualified, experienced Process Engineering team is eager to assist you to resolve your process related challenges.

Romaco China Solids Process Center is a single doorstep to provide you the professional assistance for all your questions relating to High-shear granulation, Fluid-bed Granulating - Drying - Coating - Hot melt coating, Tableting and Tablet Coating process for Pharmaceutical, nutraceutical & non-pharma industry. We understand the solids process very well! Are you interested to know more about it?

Poor flowability of product

Product stability

Variation in content uniformity & release profile

Multi-particulate coating problems

Wet & Hot melt granulation & coating issues

Lack of effectiveness of the functional coating & homogeneity of the coating

Heat & moisture sensitive product

Tablet compressibility issues

Process capability improvements

Developing a new product from powder to the coated tablet

Replacing an existing material & process equipment

Scale-up/Scale-down of manufacturing process

Improving process yield/ energy consumption/ process time

Product development cost reduction

Support for the entire process from granulation to tableting and coating

Manufacturing process development, optimisation & scale-up support from lab scale to commercial scale

Troubleshooting

In-depth knowledge of standard and novel excipients used in pharmaceuticals and nutraceuticals

Quality & Regulatory compliance assistance

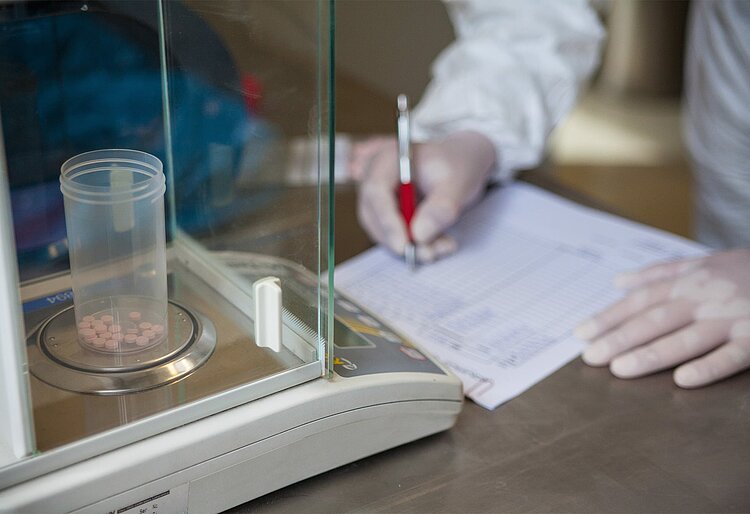

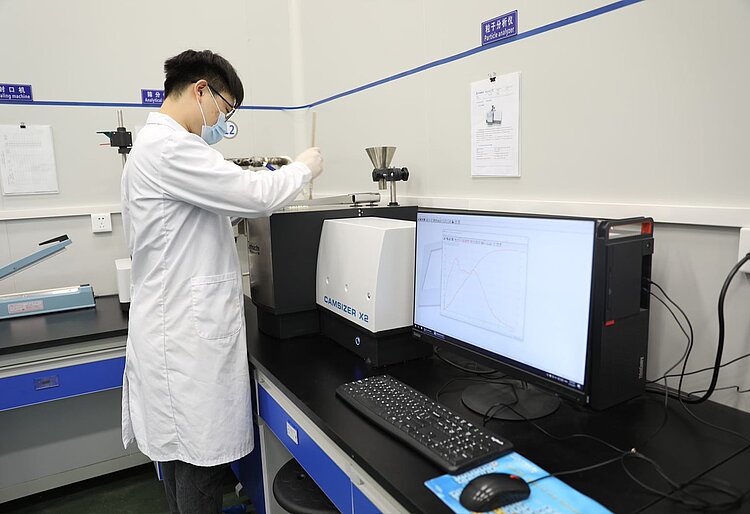

In-process testing & material characterisation support

Comprehensive analysis of all required specifications for powder, granule and tablets

Expert guidance for development of tableting for special products and geometries

Design of Experiment (DoE) based approach to study the impact of process parameters and material variables on intermediate stages and final products

Quality by Design (QbD) & Quality Risk Management (QRM) assistance

Comprehensive expertise, simulation tools and test possibilities

Ventilus® Lab (Range: 0.4 – 4kg)

Ventilus®150 (Range: 7.5 – 75kg)

Granulation Line IGL 150 (Range: 20 – 60kg)

R&D tablet press KTP1X

Commercial scale tablet press K420 & S710

Tablet coater TPR 100 Optima (Range: 10 – 100kg)

Material Charcterisation instruments

Our expertise covers the whole processing process. We help with tableting expertise, but we also help you optimise the flow behavior or the compressibility of powders and granules. Furthermore, if required, we support you in choosing the right coating solution for final tablets.

You want to send test materials? Please send us your MSDS: