Plastic ampoules are normally marketed in multiple formats, arranged vertically or horizontally into cartons. This kind of package is applied both for sale to end users and to healthcare facilities.

Considering this type of configuration, plastic ampoules require large, sturdy cartons.

Prior to the cartoning process, data such as expiry date, product composition, brand, lot number, may be applied directly on the product, via printing and labelling.

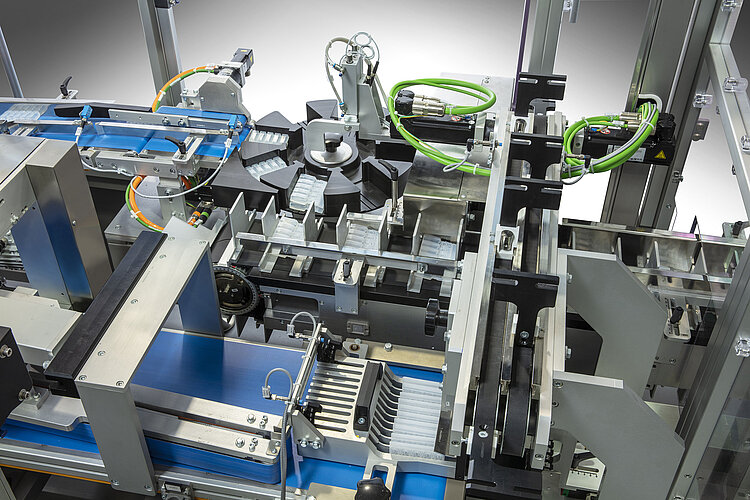

Handling of light and unstable products

Multiple products to be stacked vertically or horizontally inside cartons

Variable data to be labelled or printed directly on unstable products, on more than one side

Automatizing the whole process, minimizing operators’ intervention

Including patient information leaflet/booklet in the package

Preventing damages to product/label

Handling of vertical plastic ampoules just as received from the upstream BFS machine

Automatic labelling of each single plastic ampoule, both on front and back side, and even in the top plastic holder, if present

Printing and checking of variable data printed on the labels

Automatic station for manual reintegration of good products rejected for wrong packaging (missing leaflet/wrong printing on carton)

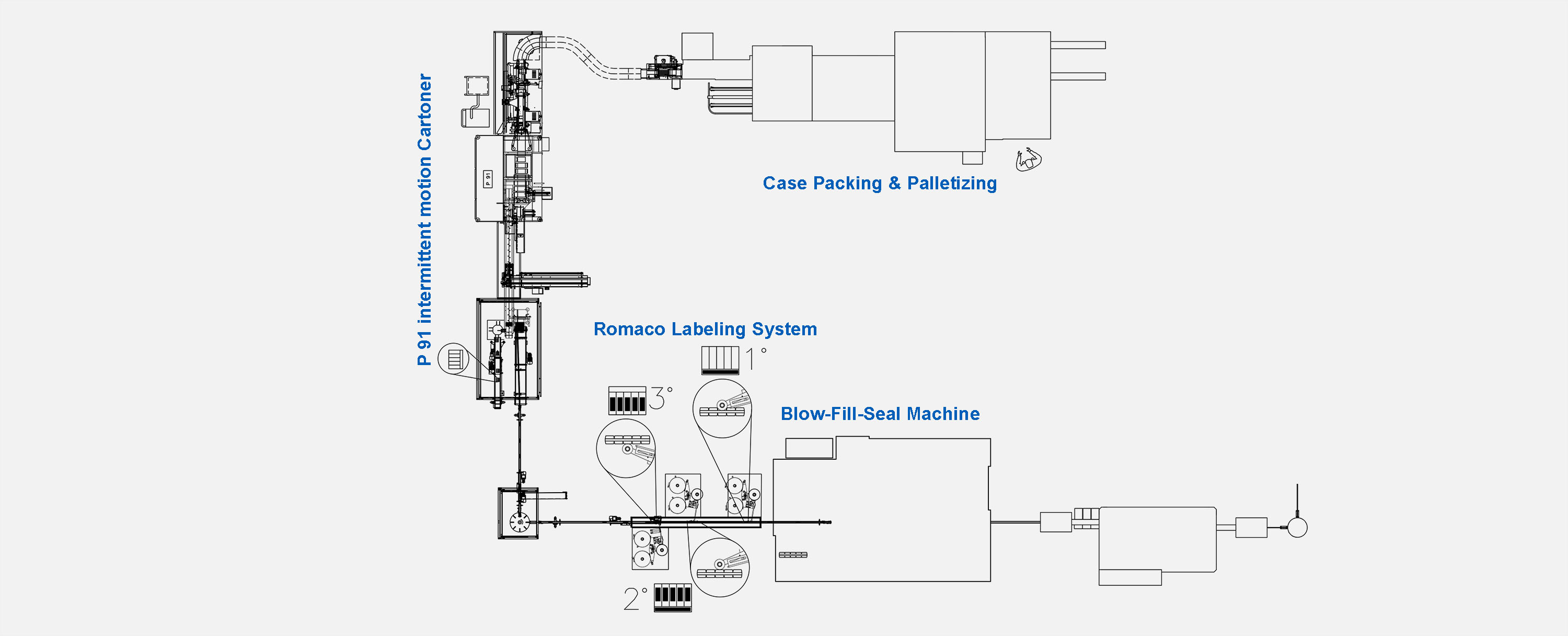

Two automatic feeding units working alternatively on the same machine, according to the format loaded, for horizontal packs and vertical packs

Positive and controlled handling of each product

Infeed available as multiple standing rows or laid-down stacks of products

Possibility to integrate leaflet/booklet infeed

Possibility to integrate vision system of choice to monitor each process step

Packaging solution for plastic ampoules from blow-fill-seal machine through labeler, cartoner (P 91), case packer to palletizer, including track and trace and aggregation.

Precisely labelling multiple unstable plastic ampoules on all fronts and packing them in different configurations is now possible with Romaco packaging line.