The CoTech pilot plant in Barcelona, Spain, offers you well documented tests and studies with regard to the coating manufacturability, coating quality as well as coating speed and efficiency of your product or product ideas.

Increase of bed product level

Stops for adjustment in bed to spray gun distance

Lack of homogeneity of the coating

Lack of effectiveness of the functional coating

Scaling up of the manufacturing operations to meet the commercial requirements

Minimisation the resources during the scale-up processes

Delays in manufacturing process

Reproducibility and robustness of the process

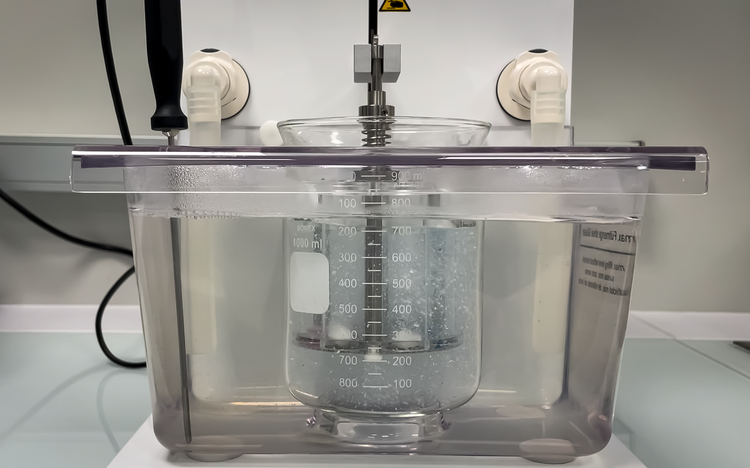

Tests of various tablet sizes, shapes and materials concerning the film coating results

Tests of various coating materials concerning the film coating results

Tests of min/max batch size and the effect on coating results

Scale-up trials

Spry loss optimisation

In-process coating analysis for coating optimisations by camera systems

Definition of best working parameters for each product

Lab & pilot plant drum coaters for batch sizes from 0,75 L to 75 L

3D printer for baffle design adjustments

Various analytical instruments

Expert team

Our expertise covers the whole film coating process. In addition to the CoTech services, we also help you to optimise the dynamic movement of the tablets inside the drum by means of customised deflectors. Furthermore, if required, we support you in choosing the right coating solution for the final tablets.

You already know what you want? Here are some questions to help us conduct your test.

You want to send test materials? Please send us your MSDS: