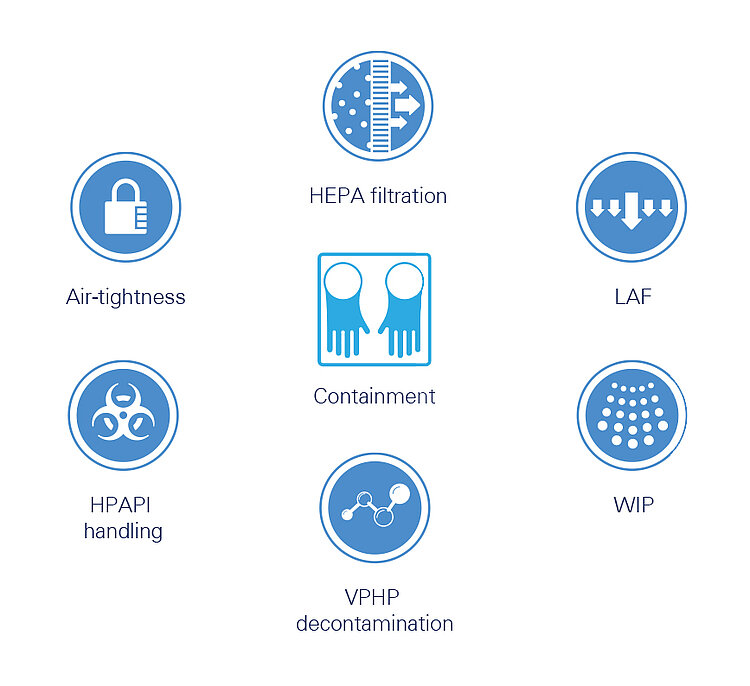

When dealing with sterile pharmaceutical productions there are two main aspects to be considered: products’ protection and operators’ safety.

It is therefore of utter importance to minimize human intervention to reduce the risk of product contamination and guarantee the highest protection towards the operators.

The isolator, being a physical barrier, allows the implementation of a successful contamination control strategy, with full automated process and monitoring system, as well as minimum human intervention.

Product sterility

Operators’ safety

Contamination

Process control

Production efficiency

Bio-decontamination

Assembly of parts and loading of components in line with the aseptic process

Maintenance costs

Downtime

Energy consumption

Stringent guidelines

Validation

Data integrity

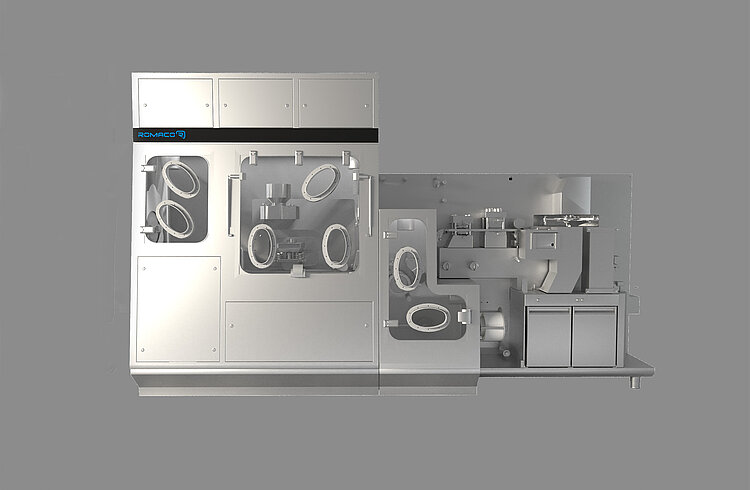

High grade stainless steel isolator, fully integrated on machine base

GMP Grade A environment (ISO 4.8)

Laminar Air Flow

Dedicated AHU

Pressure management

Air tightness compliant to Class III (according to ISO 10648:2)

Automatic leak test (including bellows leak test)

Integrated WIP/CIP systems

Bi-Bo filter units

Inlet & Outlet HEPA 14 filters

Enhanced ergonomics

Containment up to OEB 5

Energy-saving design

Optimized automatic bio-decontamination systems (VPHP and aHP)

Aseptic transfer systems

Full compliance to GAMP 5, 21 CFR part 11

Romaco isolators allow the implementation of a successful contamination control strategy, with full automated process and monitoring systems, minimizing human intervention and guaranteeing operators’ safety.