The laboratory InnoTech in Steinen, Germany is the expert centre for all your questions relating to granulating, drying and coating.

Formulation development, feasibility, process optimisation and troubleshooting. The well-equipped laboratory InnoTech provides you with direct access to a wide range of expertise in processing solids.

With state-of-the-art equipment, the InnoTech particularly focuses on optimising your granulation, (fine) powder and pellet coating processes.

Developing a new product

Expert advice on raw material

Poor flowability of your product

Replacing an existing excipient

Improving your yield/energy consumption/process time…

From feasibility trials and formulation support to scale-up and process optimisation

In-depth knowledge of standard and novel excipients used in pharmaceuticals and nutraceuticals

Intensive test patterns with results documented in detail

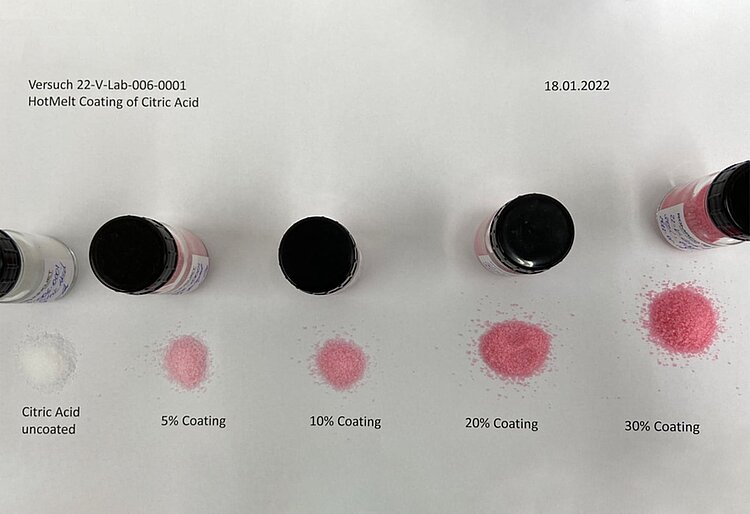

Several processes: high shear mixing and granulation, fluid bed drying, fluid bed granulation, fluid bed coating of powder and pellets, hot melt coating in lab scale, pilot scale and production scale available

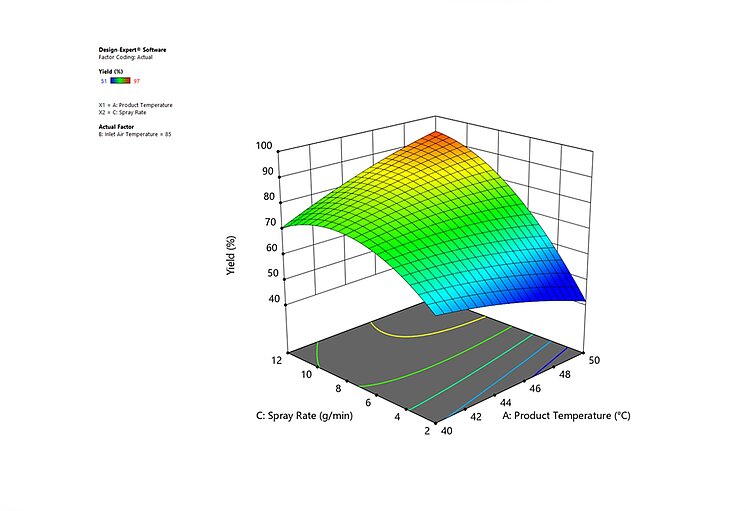

We implement a design of experiment (DoE) based approach to study the impact of process parameters and material variables on intermediate stages and final products

We offer training sessions for operators and/or maintenance incl. troubleshooting

Scale-up realized with an in-house developed software, trials on a Ventilus with up to a 150L

Expert advice on raw materials, compatibility of components and processes

Novel approaches for clean label granulation and coating, mainly in nutraceuticals

Ventilus® Lab

Ventilus® Pilot

Ventilus® Production Scale

Top spray and bottom spray technology

Camsizer X2

Many other analytic tools

Expert team

Granulation of ALGAE EXTRACT (e.g. from Chlorella or Spirulina) without additional granulation aid (→ 100% natural). Goal: Improved flowability and handling properties, zero dust, direct compressibility and stable tablets.

To speed up the processing of your request, please answer a few essential questions.

For your request you can download and send it by e-mail to: [email protected]

Or simply send us a formless e-mail.

You already know what you want? Here are some questions to help us conduct your test.

You want to send test materials? Please send us your MSDS: