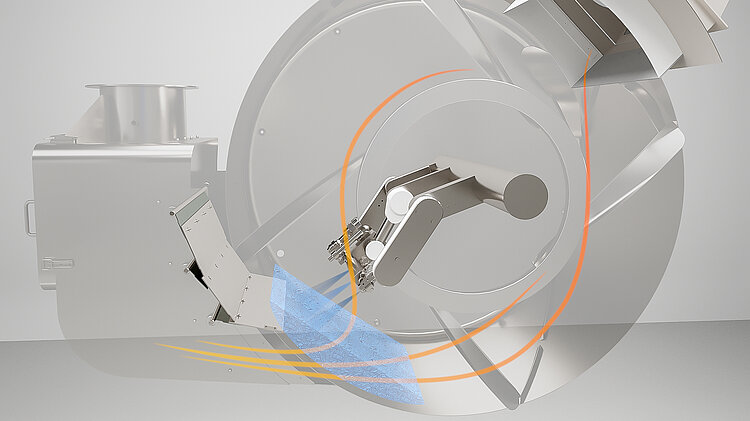

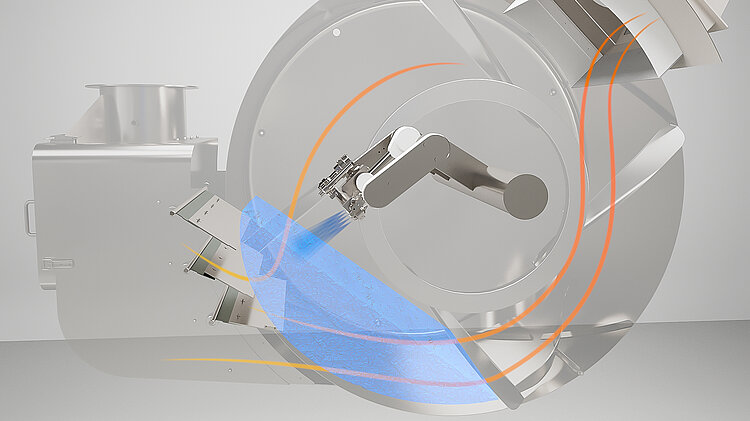

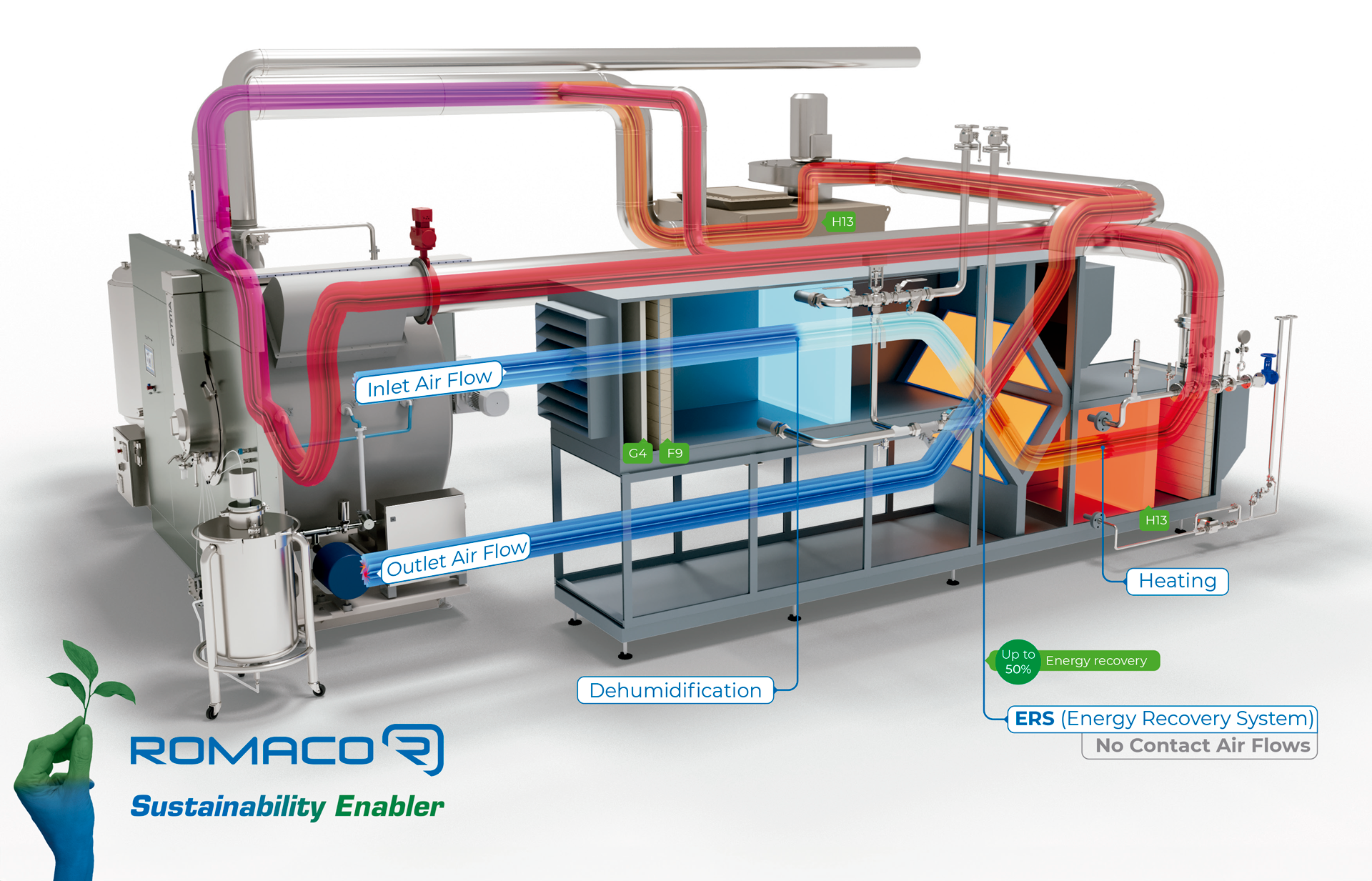

Fully automatic perforated coating pan without mechanical adjustments for film coating of tablets and pellets suitable for aqueous and organic coatings.

Performance: 7.5 L to 900 L

The OPTIMA Tablet Coater is a film coating machine based on perforated pan technology.

Its high technology allows an automatic adjustment control of the flow, avoiding the damp, saving coating and optimizing the process time.

| Tablet Coaters | Capacity (l) | Dimensions (mm) | |||||

|---|---|---|---|---|---|---|---|

| Model | min. | max. | A | B | C | D | E |

| TPR 50 Optima | 7.5 | 75 | 3,210 | 2,254 | 2,799 | 1,276 | 1,510 |

| TPR 100 Optima | 15 | 150 | 3,210 | 2,260 | 2,799 | 1,276 | 1,538 |

| TPR 200 Optima | 30 | 300 | 3,210 | 2,321 | 3,413 | 1,615 | 1,798 |

| TPR 300 Optima | 45 | 450 | 3,510 | 2,542 | 3,975 | 1,845 | 2,130 |

| TPR 400 Optima | 60 | 600 | 3,710 | 2,785 | 4,154 | 1,937 | 2,217 |

| TPR 500 Optima | 75 | 750 | 3,840 | 3,050 | 4,306 | 1,953 | 2,323 |

| TPR 600 Optima | 90 | 900 | 3,840 | 3,340 | 6,275 | 2,730 | 3,545 |

TP R Optima Coater leaflet 2.4 MB (pdf)

* Approximate data / loading levels may change depending on tablets shape and density

*Tests performed under specific conditions