Hygroscopic products are challenging to compress, difficult to store and the fragile effervescent tablets need to be carefully handled not only during feeding, but also throughout the whole manufacturing and packaging process. They’re easily affected by mechanical stress, light, air and moisture.

Stability of active ingredients

Packaging material

Handling of effervescent tablets

Sustainable production

Capacity requirements

Tablet hardness and/or formulation

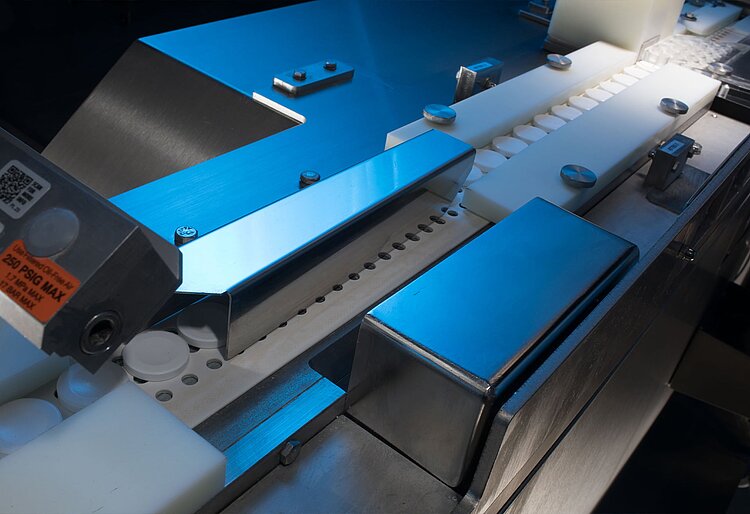

Safe and gentle product handling

Easy and controlled direct connections

Use of our laboratory PacTech to test your application

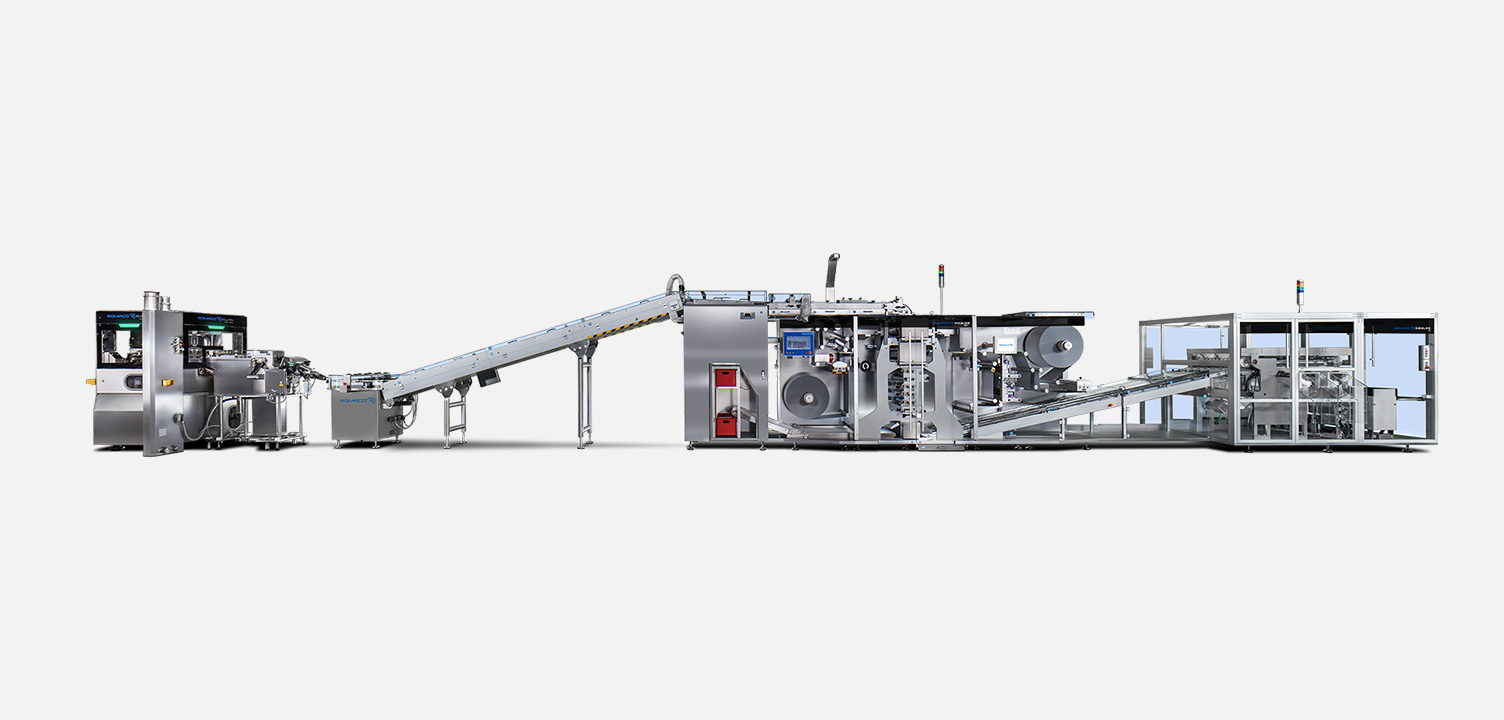

One stop solution from powder to palletizer

Focus on your product, its properties and the resulting tableting and packaging requirements

A tablet press (Kilian KTP 720X), transfer (Kilian TabTrans), strip packaging (Siebler HM1 E), and transfer (Siebler FixTrans)

Do you have to process fragile products like effervescent products? Our laboratory PacTech can help you find the right customised Siebler solution. Moreover, our PacTech supports you e.g. with speed demonstrations as well as existing tablets and material analysis.