Romaco Macofar also offers a wide range of peripherals to complete powder and liquid filling production lines, to further the operations and all process-related activities.

The production process can be optimised and customised according to each customer's specific requirements.

The Tunnel is size parts free and designed to sterilise and depyrogenate glass vials by a laminar flow of hot air at a temperature of 320° C. The depyrogenation process is continuously monitored and process parameters can be easily recalled and edited.

Depacking machine for bottles packed in thermo-shrunk plastic. The machine automatically cuts and removes the thermo-shrunk plastic, freeing the bottles from their package. Thanks to the brushless motorisation, all operations are smooth and maintenance needs are very low.

Cleaning of the external surfaces of filled and capped containers from potential residues.

Visual inspection equipment to check product quality and container aestethics.

In-line integrity testing of primary packaging.

Wrap-around labelling machines suitable to be integrated with printing devices and vision systems.

User-friendly and ergonomic automatic bin lifting column with integrated valve management for powder transfer into the filling system.

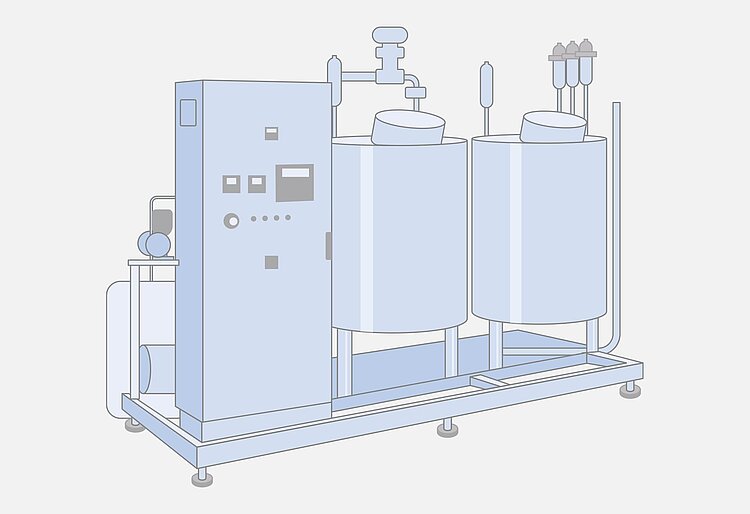

Clean In Place and Sterilise In Place on skids, fully integrated and managed by filling machine HMI.