Romaco Noack also offers a wide range of peripherals to match the various Blister machines. These peripherals enable the production process to be further optimised and aligned to each customer's specific requirements.

Smart solution to implement a lifting function in your strip machine to increase efficiency, also gives ergonomic support during the operation.

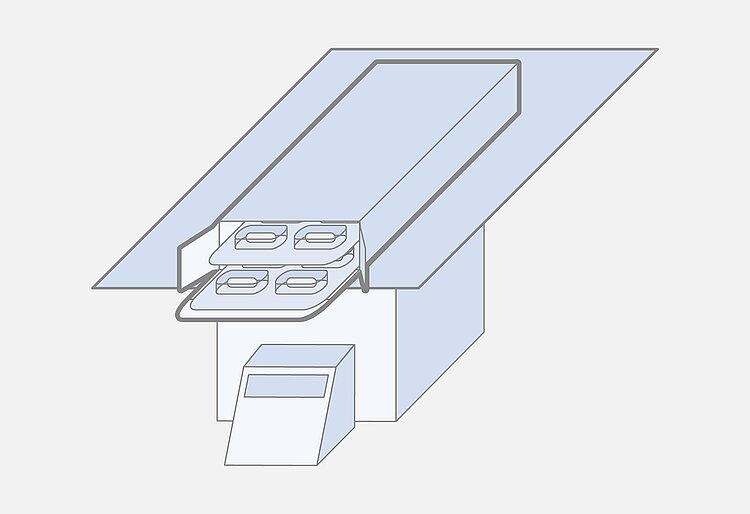

Blister feeding for any product specification, feeding system for blisters with multiple products.

Quick change of forming and lidding foils, user friendly lifting equipment saves time and improves workplace ergonomics.

Keep a stable temperature to enable safe and efficient production.

Most performing industrial vacuum cleaner for the most demanding applications specific for pharma and chemical packaging - high cleaning standards, compact design.

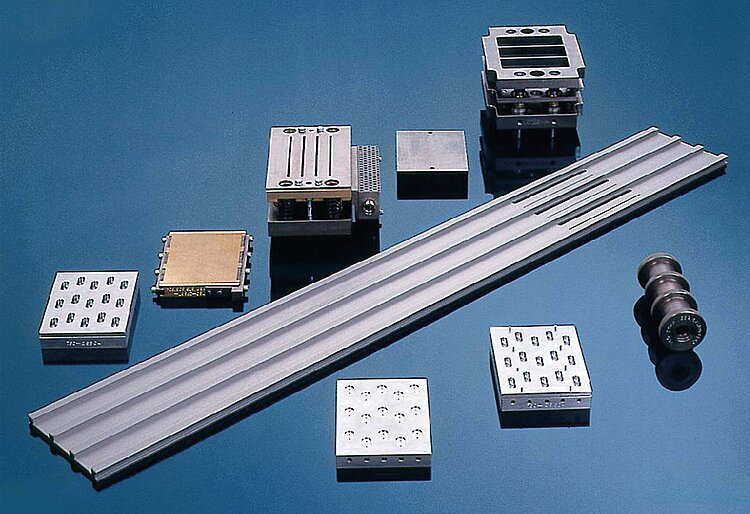

More than 40 years of experience in format parts design result in quick format changes, high outputs, consistent quality monitoring, fast lane service and ensuring functionality.

Reliable precision parts for machines, products and packaging are developed to specific customer requirements and each format part is thoroughly tested in the Romaco format center before it is sent out.

High precision checkweigher can be integrated easily into the production line without reducing throughput.